Choose your country or region

- Europe

- Spain

- Catalonia

- Portugal

- United Kingdom

- International Version

Barley Warehouse

Seed to Seed

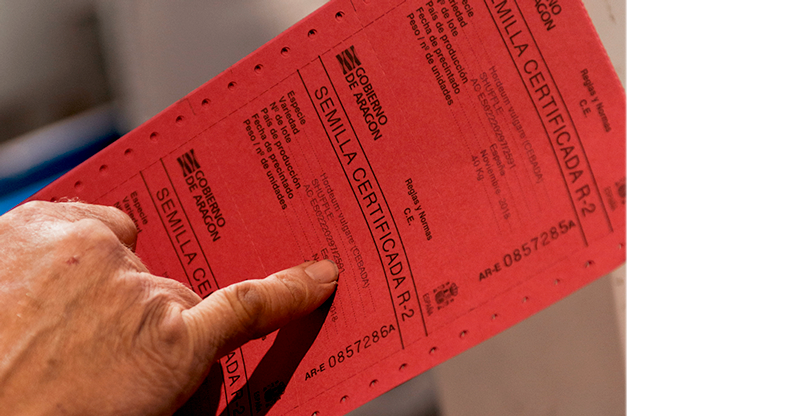

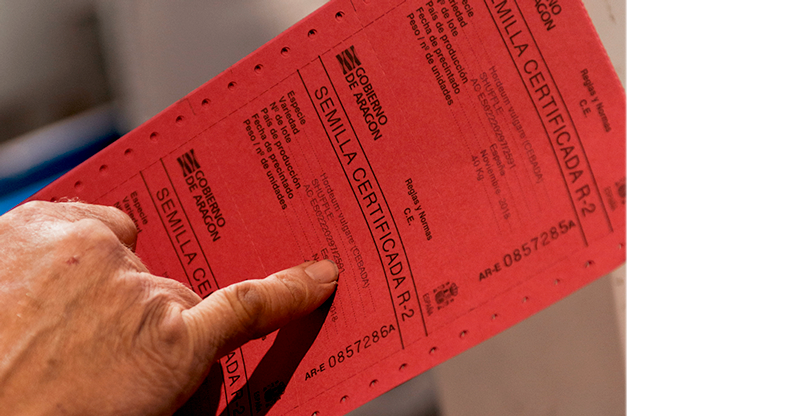

10:01 — At the barley warehouse, the seeds are the stars of the show so they receive the treatment they deserve. They are cleaned and purged to remove any impurities that won’t be used, and the grain is packaged. This is when we begin the certification process. “In order to guarantee that every barley seed is in the optimal state for sowing, we must be very thorough when identifying their variety, generation, where they came from and where they are going, etc.” explains R. Camarasa, agricultural farmer and entrepreneur.

This process is made up of two parts. First we put the barley in sacks of different sizes (40 kg or 1,000 kg) and then we label them with the reference number that will serve as the batch identification number. “The label is like the registration number of each seed,” says R.

This identification number, which has been reviewed, validated and assigned, will facilitate the traceability of the barley and guarantee its certified quality.

“We know where each barley grain is going at all times”

R. Camarasa

Damm Plant

Casks: sustainable freshness

18:42 — When we think about drinking an Estrella, the first thing that comes to mind is the iconic 33 cl bottle, but we tend to forget about the cask, a very sustainable container that cares for the product. D. Sancho, head of the bottling plant, is convinced of its benefits: “As it is opaque and made of stainless steel, the cask efficiently preserves the beer and protects it from external threats such as light,” he says. And that’s not all, this cask can also be returned and the turnover is very high, which means that the product is guaranteed to always be fresh. “This type of packaging has the fastest consumption,” says Sancho, who also highlights the sustainability of the casks, which have a long useful life and a highly efficient filling system: “From the moment it enters the line until it leaves it, only 20 minutes will pass, while a bottle will stay for between 3 and 4 hours.” Therefore, this is a simple and sustainable format that fully preserves the freshness of our traditional Estrella. Long live the cask!

“Because it’s opaque and made of stainless steel, the cask efficiently preserves the beer”

D. Sancho

Tank Installation

More tanks for more Estrella

19:15 — It has taken a few months, but we can now say that our family of storage tanks has increased. Thanks to this new equipment, more beer wort will be stored right after the boiling process and the addition of the yeast, and it will remain here to ferment for a week and to rest for another two. Moreover, the cellar has been enlarged to fit more tanks of Estrella that are ready to be bottled.

Moreover, the cellar has been enlarged to fit more tanks of Estrella that are ready to be bottled.

This new infrastructure will guarantee that our beer can be honed to perfection so that it can travel even further.